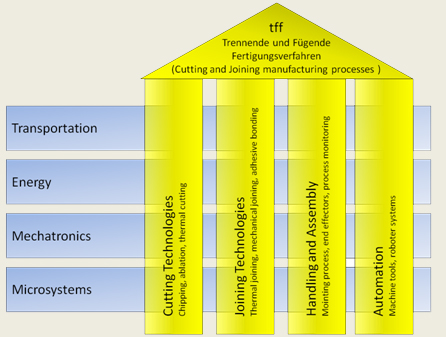

| Prof. Dr.-Ing. Prof. h.c. Stefan Böhm Fachgebiet Trennende und fügende Fertigungsverfahren, Institut für Produktion und Logistik, Kassel Profile of the department for Cutting and Joining manufacturing processes The department for production engineering and machine tools (former designation of the department for Cutting and Joining manufacturing processes) was founded in 1988 to strengthen the teaching in the field of manufacturing technology with regard to industrial application. Head of the Department was Prof. Dr.-Ing. Franz Tikal. With the retirement of Prof. Dr.-Ing. Eberhard Pauksch in 1999 the task of the department of Metal Cutting Technology was also received at the Department of Production Technology and Machine Tools. Since this time the department affects many aspects of industrial production. Besides the classical problems of cutting the organization of production, the assembly technology and the technical management were tasks of the department. Through the appointment of Prof. Dr.-Ing. Stefan Böhm at the 1st of April 2010 to the department direction the denomination of the department was changed in department for Cutting and Joining manufacturing processes. This name reflects the expansion of the teaching and research tasks at the joining processes and production automation. There are now in teaching and research cutting, joining, automation of production processes and for the manufacturing processes necessary handling systems. Main fields of Research Since North Hessen is dominated by industrial production in the area of transportation and energy, these are in addition to the mechatronics and micro-systems in the focus of applications.

The Joining manufacturing processes are key processes in the production process. The joining technology works in all phases of a product development process: it must be considered in the product planning and development and construction, it determines much about the production, the potential uses of a product and it is for the maintenance and repair of a product as important as the recycling and disposal. The joining of different materials with high process safety and durability at the same time more easily separable at the end of the product lifecycle is a task that only can be solved with new technical join-ing processes and equipment, with innovative detachable connections and with an integrated, multiphase simulation, calculation and evaluation of jointed components under consistent account of the whole product life cycle. Teaching In the area of teaching, the department deals with the previously described manufacturing methods, and handling and automation. The current courses are available on the website of the tff in teaching / courses are available. For almost 20 years intensive cooperation agreements with South American universities and industrial facilities in the area of teaching and research. These are complemented by cooperation with Russian, Chinese, Georgian and Indian institutions.

The department for Cutting and Joining manufacturing processes includes six scientific, three technical and 15 student employees who are supported by numerous students who work on their diploma thesisís For the research and teaching activities of the department 150 square meters of office space and 800 square pilot and laboratory space are available. » Back to Who is Who |

|

|