A Novel Technology for Highly Sensitive Gas Sensors

Today, modern industrial applications require precise knowledge of any physical parameter involved in a fabrication process in order to maintain constant high quality and reproducibility. Precise sensing is the key to this knowledge. A new universal sensor technology, under development at INA, can meet these requirements and open a door to a new order of magnitude in sensitivity and selectivity, at small sensor dimensions and low operating cost. Its sensing capabilities include all properties, which can be transferred to a variation of the parameters of a laser resonator in any way. This includes but is not limited to the measurement of length, temperature, electric and magnetic fields and gas concentration.

The concept behind the novel optical sensor is to use the reaction of a specially tailored semiconductor laser to slight variation of its resonator parameters. As such a laser device is very small, it allows the assembly of very compact sensors being highly sensitive and mechanically stable. A semiconductor laser device geometry facilitates to tune the laser to emit at two equivalent modes. This equilibrium provides a pronounced mode competition, which is extremely sensitive to changes in the gain curve, which itself highy depends on the properties of the resonator.

For measurements of length i.e. one of the resonator mirrors can be attached to the object to be monitored. Variation of its dimensions will immediately influence the resonator’s properties. This can be utilized to destroy the equilibrium between the two oscillating modes and extinguish one, changing the laser system’s oscillation state from two mode to single mode.

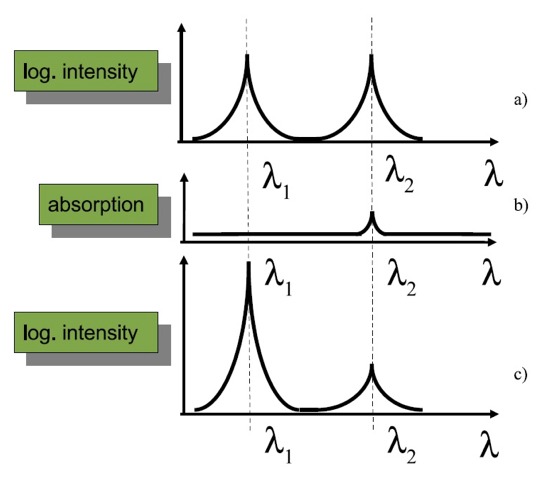

For gas sensing applications one of the two modes of identical intensity is tuned to a characteristic absorption line of the gas molecules to be analyzed. Introducing even an extremely small number of molecules into the resonator can provide a sufficient local spectral gain reduction by absorption in one of the two modes and cause a characteristic intensity difference (see Fig. 1). This yields precise quantitatve information on the gas concentration.

Gas sensing in particular requires not only high sensitivity, but additionally has extreme requirements to selectivity. It is not only necessary to know if there is a gas present, but also which gas. However, for the presented sensor solution this is no problem, as each gas has a specific infra red (IR) fingerprint, for which the sensor can be tailored in a way that ambiguity is minimized to insigificance. Conventional gas sensors, which are available at the moment, bear limitations at low gas concentrations and require a photomultiplier system to integrate the light output over a period of time. In contrast to this, the new technology measures the mode competition by means of ”relative intensity noise” (RIN), which is measured electronically instead of optically.

Technological Advantages

- High sensitivity due to the highly sensitive mode competition.

- Very fast sensing at slight parameter variation.

- Easy adaption of sensor system to specific measurement requirements.

- Spectral tunabilty of the sensors allows selective addressing of different gases.

- Possibility of integration into an array, allowing detection of a broad range of substances.

- Small dimension laser diodes, few microns, make very compact sensors, which leads to a cost effective device.

- Use in hazardous environments is possible with an external cavity.

- Optical as well as electrical readout is possible.

In a preliminary setup the suitability of RIN measurements as an indicator of the lasing state of a laser has been investigated. For this purpose a two section DFB Laser, which is capable of two mode oscillation was used. The emitted light is coupled into a tapered fiber and guided to either an electrical- or an optical spectrum analyzer (ESA/OSA) by means of an optical switch. The ESA is equipped with a high speed photo detector to measure noise. Two approaches of achieving stable two mode lasing involve keeping laser current constant and varying phase current, as well as vice versa. Within the selected current range a shift from single mode oscillation at 1541 nm to single mode oscillation at 1544.5 nm was observed. In between, two mode lasing was achieved.

Corresponding spectra from the OSA and ESA were recorded as a function of laser current. They were correlated and the behavior of the maxima of the RIN spectra evaluated in respect to intensity and position in the frequency domain. A transition from higher to lower noise frequency can be observed, and the two mode state identified, which delivers a conclusive means of determining the lasing state from RIN spectra alone.

At the moment possible indicator substances in the medical sector are beeing evaluated. A gas cell has been designed and built, which allows control of pressure and temperature inside. It is being prepared at the moment for conventional spectroscopy of gases to identify absorption lines in the NIR range.

Due to the possibility to tailor this sensor for individual measurement tasks, the possiblilities of appliccation for this sensor system are very broad.