This page contains automatically translated content.

Smart steel to protect structures from earthquakes and other risks

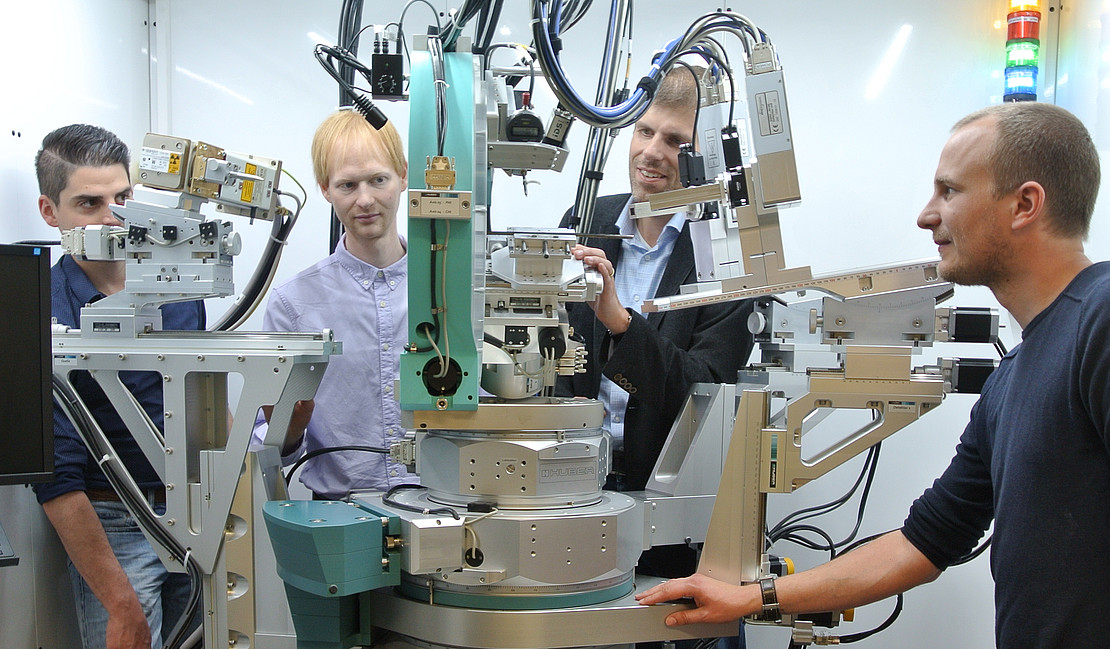

Image: University of Kassel.

Image: University of Kassel.Smart materials such as shape memory alloys have so far been used mainly in the form of small components, where they are already saving the lives of many people, for example in biomedical technology in the form of vascular supports known as stents. Exploiting the unique possibilities of these alloys is also attractive for many other industries. From aerospace to automotive to construction, there are already a multitude of application ideas. However, the cost of the alloys available to date is mostly too high for cost-justified use in these industries. "Steels, or more correctly in scientific terms iron-based alloys, with shape memory effect are a promising alternative to existing alloys here, as they are inexpensive to produce," says materials scientist Prof. Dr.-Ing. Thomas Niendorf of the University of Kassel. In one of his research projects funded by the German Research Foundation, led by his colleague Malte Vollmer, the new alloy and the underlying process were developed together with colleagues from TU Bergakademie Freiberg and IFW Dresden. The results have now been published in the latest issue of the renowned research journal Nature Communications.

The researchers succeeded in qualifying one of these alloys for new applications in the construction industry by means of suitable chemical modifications. They used as a basis an iron alloy that already exhibited smart properties, known as pseudoelastic behavior, but did so solely in the form of small laboratory samples. Using new alloy additives and an adapted process chain, they are now adjusting the alloy so cleverly that the previous limitations in component size have been overcome. The result is the world's largest single-crystalline structure realized in a smart steel, a breakthrough on the way to industrial use.

"Applications in the construction industry will benefit significantly from this. The smart steel will make it possible to protect bridges and structures in vulnerable regions from damage and destruction caused by earthquakes or even high traffic loads," Prof. Niendorf is certain. "Essential is its considerable pseudoelastic damping capacity, which significantly reduces the loads of corresponding critical events and thus protects structures and can save human lives." Intensive talks are already underway with civil engineering colleagues in Kassel to use the new smart material in a targeted manner. A more far-reaching research project has already been initiated with the SmartCon project under the leadership of Prof. Dr. Bernhard Middendorf (Department of Civil Engineering). Niendorf sees enormous potential for the German economy in the new smart material: "From fasteners for wood and solid construction to reinforcement elements for concrete structures, its use is conceivable. The German steel industry relies on highly specialized steel grades, while the construction industry also relies on advanced building materials such as ultra-high-strength concretes. . A high level of interest from these industries, which are important in Germany, is evident"

Shape memory alloys are based on a so-called martensitic transformation, which is fully reversible. After deformation, they return to their old shape when heated, which has given them their name. The search for new shape memory alloys is one of the research priorities of Prof. Dr.-Ing. Thomas Niendorf. He has held a professorship in metallic materials at the University of Kassel since 2015. In addition to shape memory alloys, he conducts research on 3D-printed objects; in both cases, evaluating the properties and reliability of the realized materials is an essential part of his team's research.

Original article:

www.nature.com/articles/s41467-019-10308-8

Contact:

Prof. Dr.-Ing. Thomas Niendorf

University of Kassel

Institute of Materials Engineering

Department of Metallic Materials

Tel.: 0561 804 7018

E-mail: niendorf[at]uni-kassel[dot]de