Development of Solar Thermal Energy Storage System

Focus

Value addition to agricultural products through capturing and storing solar thermal energy at medium temperature to ensure continuous operation of suitable post-harvest food processing in the absence of sunlight

Abstract

Agriculture contributes 21.4% to the national GDP of Pakistan with 65% of its population either directly or indirectly engaged in agriculture. Pakistan like many other developing countries is affected by food insecurity and poverty. Approximately 44% of global Food Loss and Waste (FLW) takes place in developing countries mainly due to financial constraints faced by the small farmer which lead to orthodox practices causing a reduction in both quality and quantity of food. Equipping farmers with small-scale on-farm processing units using renewable energies will not only enable them to afford the latest processing techniques but will also help to enhance product quality and reduction in food spoilage. Among all the renewable resources, solar energy is the most promising one due to a huge amount of solar irradiation reaching earth. Pakistan is blessed with abundant sunshine with mean daily solar radiation of 4.3 kWh/m2 which is higher compared to the global annual mean daily 3.6 kWh/m2. Therefore, the development and adaptation of solar-based technologies for rural communities should be promoted in Pakistan. Unfortunately, solar thermal-based food processing can be carried out during daytime only which means only a limited quantity of food can be processed. Food is a perishable commodity and is suspectable to physiochemical deterioration after harvesting therefore it is paramount to process the food as early as possible. The most common source of thermal energy generation in agriculture food processing during off-sunshine hours is a biomass boiler. One of the prominent hurdles in the adoption of biomass as a reliable source of energy is its low energy density. On the other hand, rural farming community consumes 80% of the biomass in traditional cooking stoves to cook food. What if a system can be developed which can make the solar thermal energy available during off sunshine hours? A Latent heat storage (LHS) system utilizes a phase change material (PCM) which can store and release thermal energy. Moreover, the LHS system offers high-density energy storage and releases at a nearly constant temperature. Currently, PCMs have been adopted in various fields including, solar drying systems, heating and cooling of domestic, refrigerators, solar power plants, waste heat recovery, photovoltaic electricity generation and domestic hot water systems.

The current study is the continuation of 2.5 m2 Scheffler concentrator based Latent heat thermal energy storage system. In this study a large-scale standalone Latent heat thermal energy storage will be developed to harness the energy generated by 10m2 Scheffler concentrator which in theory will enable higher volume of energy to be stored at medium temperature. The system will be able to exchange thermal energy with various food processing system running on different working fluids (air, water, oil) thus provide a facility to the farming community to prosses their produce even in the absence of sun.

Project's aims

This project aims at R&D on appropriate Solar Thermal Energy Storage System using Phase Change Material (PCM) for medium temperature decentralized post-harvest processes in a rural community. This will improve the living standards of small entrepreneurs and rural communities as well will help minimize food loss by providing on-farm continuous processing of agricultural products.

Literature Review

- Food loss and wastage

Food loss and waste (FLW) is regarded as a major threat to food security as well as to the economy and the environment. Approximately 1.3 billion tons of edible food which amount to one-third of all food produced for human intake is lost and wasted. In developing countries, FLW takes place mainly in the post-harvest and processing stage, which amounts to 44% of global FLW. The causes of high FLW in developing countries are poor practices, labour and financial restrictions, technical and technological limitations, and lack of proper infrastructure for transportation and storage. Pakistan has diverse agro-climatic conditions, varying from tropical to temperate, which favours the growth of 21 different types of fruits. The market worth of the fruits produced in 2006-07 is estimated to be 97 billion rupees which is nearly 8% of the agriculture value added in the year.

- Importance of food processing preservation

Food processing is the process of converting agricultural products into food or one form of food into the other. Food processing dates back to the time when communities first came together thousands of years ago. All foods are composed of biological materials that start to decay as soon as they are harvested. Processing delays or stops this deterioration process and thus allows foods to be preserved for longer periods.

- Small-scale on-farm processing

Many small scales of on-farm food processing equipment have been developed to facilitate small farmers of developing countries. These include milk pasteurizer, solar roaster, essential oils distillation etc. The purpose of these processing facilities is to enable farmers to process their products at the farm level using renewable resources to slow down the physiochemical degradation of their products.

- Thermal energy storage

Energy storage is essential for any system that depends on solar energy. A good solar thermal system should store surplus energy and utilize it whenever needed. There has been a rising interest for the past three decades in the latent heat thermal storage (LHTS) technique which has emerged as a better option over sensible heat because Latent heat storage methods offer high-density energy storage and temperature fluctuation between storage and release of energy is far less compared to sensible heat storage. In LHTS units, phase change materials (PCM) are used which undergo a change of phase (solid to liquid and vice versa) during the energy transfer process. The key feature of LHTS systems is that the almost equivalent amount of heat energy stored in PCM during melting can be retrieved during solidification. Currently, PCM has been adopted in various fields including, solar drying systems, heating and cooling of domestic buildings, refrigerators, solar power plants, waste heat recovery, photovoltaic electricity generations and domestic hot water systems.

In light of the above discussion, it can be inferred that the latent heat storage system is a very successful technology in various fields but up till now, no effort has been directed to utilize it for on-farm agricultural food processing. The current study will focus on a novel approach of utilizing the Scheffler fixed focus concentrator to energize a latent heat storage system with a suitable PCM and to gauge the possible suitability of the system to run some on-farm agricultural food processing units.

- Aujla, K.M., Shah, N. A., Ishaq, M., & Fraooq, A. (2011). Post-harvest losses and marketing of grapes in Pakistan. Sarhad J. Agric, 27(3), 485-490.

- Farid, M. M., Khudhair, A. M., Razack, S. A. K., & Al-Hallaj, S. (2004). A review on phase change energy storage: Materials and applications. Energy Conversion and Management.

- Ishangulyyev, R., Kim, S., & Lee, S. H. (2019). Understanding food loss and waste—Why are we losing and wasting food?. Foods, 8(8), 297.

- Jegadheeswaran, S., Pohekar, S. D., & Kousksou, T. (2010). Exergy based performance evaluation of latent heat thermal storage system: A review. Renewable and Sustainable Energy Reviews.

- Zhou, Z., Zhang, Z., Zuo, J., Huang, K., & Zhang, L. (2015). Phase change materials for solar thermal energy storage in residential buildings in cold climate. Renewable and Sustainable Energy Reviews.

Methodology

- Identification of Suitable PCM

Selection of suitable PCM is the most important step in any latent heat storage because it is a difficult and complex task due to a huge number of different materials each having different characteristics (Rathod & Kanzaria, 2011). A good PCM for any system should have a melting temperature matching with an operational temperature of the system, should melt uniformly with minimum subcooling, and should be non-toxic, non-corrosive and chemically stable (Farid et al., 2004) but the most important criterion of PCM selection is high specific heat and enthalpy values along with resistance against change in melting, solidification temperature and enthalpy values with time due to thermal cycling (Kumaresan, Velraj, & Iniyan, 2011). Over the past 40 years many PCM materials like paraffin wax, salts, fatty acids and eutectics of non-organic and organic compounds have been studied (Farid et al., 2004) which gives enough scientific study material to carry out a desk study to analyze and compare various PCM materials and identify those which have high specific heat, enthalpy and good cycling stability and can potentially be used for this experiment. However significant difference exists between various studies to analyse thermophysical properties of PCMs because of different experimental characterization, Polymorphism and data evaluation (Solé et al., 2014) So, an experimental study will be conducted in which the selected PCMs will be subjected to thermophysical and cycling stability analysis in a storage tank to gauge their performance in the devised system and the best performer will be selected for the system.

- Working Principle / Design Configuration of Solar Thermal Energy Storage System

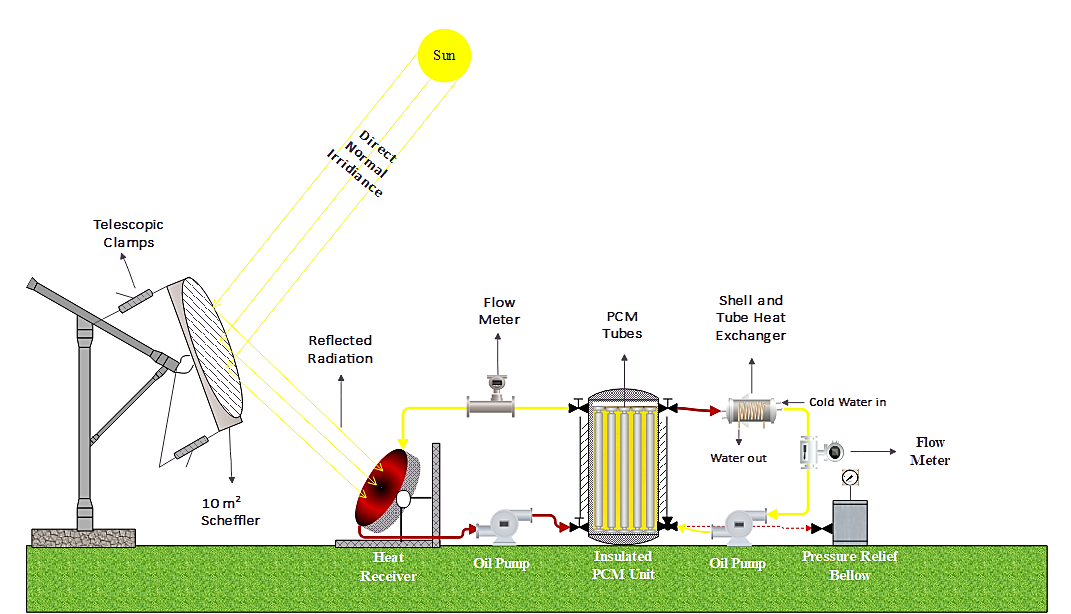

The experimental setup will comprise a 10 m2 Scheffler reflector, heat receiver, PCM heat storage tank and a shell and tube heat exchanger. The schematic diagram and working principle of the solar PCM system are shown in the following figure

The incoming direct solar irradiance (DNI) will fall at the surface of the Scheffler reflector and after converging will strike the surface of oil filled heat receiver located at the focus thus causing a rise in the temperature of thermal oil within the receiver. Heated thermal oil will flow along the insulted oil pipe from the receiver and will be introduced to the insulated PCM unit from the bottom with the help of an oil pump. After exchanging heat with PCM housing pipes, the oil will then proceed to back to the heat receiver to be reheated. This whole process will continue until all the PCM inside the tank is completely melted. An expansion below will also be connected to the oil circuit to release the extra pressure generated by heated thermal oil in a closed circuit to prevent any damage. After the charging (melting) of the PCM is completed, the valves connecting the PCM tank with the heat receiver will be closed and the PCMs will be discharged with the help of a heat exchanger by opening the other pair of valves. For testing purposes, Cold water will be introduced into the heat exchanger from one end and thermal oil of the PCM tank from the other to create a counter flow to maximize heat transfer rate and reduce thermal stresses. The rise in the temperature and amount of water will be recorded to measure the quantity of thermal energy released by the PCM tank. Many types of sensors (Thermocouples, Pyranometer, flow meters) at suitable locations will be installed with a digital data logger to record the real-time data.

- Optimization of the System

Not only a suitable PCM but various other factors also play a crucial role in the thermal performance of the system. The mass flow rate of HTF and its inlet temperature have a significant effect on the phase change processes (Jesumathy, Udayakumar, Suresh, & Jegadheeswaran, 2014). Therefore. After successful storing and releasing of thermal energy in the system, the effects of various factors like HTF flow rate, the direction of flow and inlet temperature will be analysed to discover the optimum combination of these factors to enhance the system’s efficiency.

- Application in Heat-based on-farm Agricultural Processing

The study aims to develop a thermal energy storage system designed to operate more than one on-farm agricultural process. The selection of the on-farm agricultural process to be operated by a thermal energy storage system will depend upon the operational temperature and heat storage capacity of the system. After identifying the compatible processes, an experimental study will be carried out to transfer the required thermal energy to the compatible system and the performance of the system will be evaluated.