3rd Newsletter (Workpackage 1: Solar District Heating, February 2017)

Exhibitions & Trade Fairs

- SHINE work package 1 will present results on solar district heating at the exhibition of the “Euro Heat and Power” Congress at May 14-17th, 2017, in Glasgow, UK. The SHINE partners will make a presentation at the conference, with summary of results, and have posters from all WP1 projects in the SHINE exhibition area.

- SHINE work package 2 will organize a small booth on solar process heat at the “E-world energy and water” trade fair at Febr. 7 – 9th, 2017, in Essen, Germany. The WP2 people will present posters, brochures, and videos for industrial companies interested in solar thermal. Moreover, they will contact exhibitors active in the field of energy services, consultancy, or renewables, to disseminate information and experiences of solar process heat.

- SHINE work package 3 will organize a session on “Sorption Storage for Solar Heat” at the 11th International Renewable Energy Storage Conference (IRES 2017) at Mar. 14-16th, 2017 in Düsseldorf, Germany. The conference is organized by EUROSOLAR Europe, with the aim to bring together “business” and “science”. It will take place together with the exhibition Energy Storage Europe.

Four SHINE PhD students will present their research project and latest insights, and Wim van Helden who supervises one of the PhD students chairs the conference session.

SHINE Course 16 - System Integration - University of Innsbruck

Date: June 27th to 30th, 2017

Host: University of Innsbruck, Unit Energy Efficient Buildings,

https://www.uibk.ac.at/bauphysik/

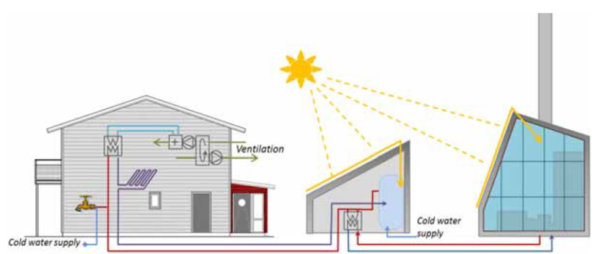

System Integration of Solar Thermal Plants

The aim of the course on system integration of solar thermal plants is to show the interaction of different elements in a solar thermal system. The topics include components and their theory, guidelines, characterization, analysis of applications, hydraulics, control systems, dimensioning and optimization, design exercise and an excursion to built examples. The different elements are solar collector, solar loop and its components, storage, auxiliary heater, building and space heating system including various hydraulics, domestic hot water demand, the climate and the control system. Practical issues concerning mounting and control will be given. The course should give insight in how to optimize these elements with respect to their function in the system. “Very good components can be put together to a very bad system”.

As software the freeware SHW (https://www.uibk.ac.at/bauphysik/forschung/shw.html.de) and a demo Version of Polysun will be used. A brief introduction to TRNSYS and solar thermal systems will be given.

The students can check that a simpler solution can most of the times improve the system without adding new components. In this case they may see that is often enough to slightly change the system setup and a few controls, for example, move a sensor or inlet/outlet tube to another position to enable cold water pre-heating or heating DHWC depending on the storage temperature.

This course will give 3 ECTS credit points and is offered within the official PhD courses of Innsbruck University. In order to get an official certificate for the course the student has to register as “außerordentliche Studierende”. Details on this procedure will follow.

The course is limited to 30 course-participants.

Tentative Schedule of the course

Day | Activities |

|---|---|

Tuesday 27th June 2017 | Welcome, Seminar on System Integration |

Wednesday 28th June 2017 | Seminar on System Integration. |

Thursday 29th June 2017 | Seminar on System Integration, Computational examples ,Roundtrip through the labs of UIBK.. |

Friday 30th June 2017 | Excursion to Solar Thermal Plants |

Saturday & Sunday / 1st & 2nd July | Voluntarily mountain tour. |

Examples for hydraulics for domestic hot water (DHW) systems with SHW

Focus on Solar District Heating (WP1)

District heating, cooling and industrial applications in Europe are now using large solar thermal systems for cost-competitiveness and higher performance. Recently some really large solar thermal installations have been installed in Europe, e.g. Vojens and Dronninglund district heating plants in Denmark with collector areas of 70,000 m2 (49 MWth) and 37,573 m2 (26 MWth) respectively, and even larger ones are planned. These figures underline the importance of further researches for large-scale district and industrial applications to keep pace with this trend in the market.

Thus there are six PhD students within the SHINE project that are studying various aspects of large scale solar thermal systems. Three deal with the detailed models of the hydraulics of collector fields and are thus relevant also for systems supplying process heat. Alireza Shantia, at the University of Innsbruck, has developed a general tool for modelling flow distribution in hydraulic networks, while Federico Bava at DTU (Denmark) has focussed on the collector fields in order to be able to optimize the cost-benefit as well as control of the field. Yoann Louvet, Kassel University, also focused on hydraulics, but in his case for drain-back of the working fluid in collectors. The other three projects focus on system aspects. Nicholás Pérez de la Mora, at the utility Sampol in Mallorca, has developed algorithms for loads, solar production and electricity prices in order to be able to optimize control of district heating and cooling plants with solar thermal input. Artem Sotnikov, at the software company Vela Solaris, has developed new models for the planning tool Polysun so that it can be used more reliably for planning smaller solar district heating systems. Finally, Martin Andersen at Dalarna University is making techno-economic studies in order to determine under which conditions solar thermal can be profitable in district heating systems. Martin started only last year, and so has not progressed as far as the others with his work.

Alireza Shantia (Flexible Hydraulic Concept and Stagnation Prevention)

Considering the diversity of solar products in the market, design concepts and hydraulic schemes in large solar systems are steadily evolving in an effort to enhance thermal performance. One of the barriers to further development of large solar thermal systems is addressed in Alrizera Shantia’s work with its focus on hydraulics that are an integral part of large solar thermal systems. The study is supervised by Wolfgang Streicher, a professor and lecturer at the Unit for Energy Efficient Buildings of the University of Innsbruck. The main objective of the research is to develop a flexible tool for evaluating complex thermo-hydraulic networks including: single flat-plate collectors, solar collector fields and district heating networks. The tool will have an emphasis on pressure drop and flow distribution. The possibilities of having a completely stand-alone tool or co-simulation are taken into consideration in the development of the tool. From a system perspective, the development builds on the mature knowledge in the field of water distribution systems, in which many numerical algorithms have been introduced over the last eight decades to handle the non-linear nature of pressure drop in hydraulic analysis of more or less elaborate isothermal systems.

A robust and stable numerical algorithm was used and further developed in this PhD study to enable calculations for meshed grids with centralized and distributed pumps in the system. The algorithm was then adapted to non-isothermal conditions in the system as the effect of temperature on density and viscosity can be considerable and should be taken into account for accurate hydraulic calculations. From a component perspective, the work has focused on deriving pressure drop model for key elements in solar thermal systems (e.g., collectors, pumps, valves, junctions etc.) in laminar and turbulent flows and also on finding pragmatic solutions to handle uncertainties in the estimation of pressure drop in transient flows, which is likely to occur partially or entirely in collector fields at relatively low flow rates. Most of the large plants in solar district heating use matched flow in the collector loop, which means that the flow rate varies over a wide range. In addition the temperature rise in a collector string can be large, resulting in different fluid properties along the string.

The tool is currently being optimized and calibrated against experimental data for both the system and component perspectives in order to check that the tool works properly for real systems. Further development might be required depending on the results of the calibration process. The major part of the work for the calibration has carried out in the MeQuSo project in Graz in collaboration with S.O.L.I.D, one of the leading companies in large-scale solar thermal energy plants. This studied plant comprises four collector fields with a total capacity of 5 MWth, all connected to a central pump station, where the heat is fed into the district heating network of Graz. Special attention is paid to the largest collector field, CF-1 (Figure 1) with a total aperture area of 2,277 m2 that has different types of collectors from a number of manufactures. This plant was chosen as there is high resolution measurement data for temperature and flow rate in CF-1, as this provides a unique opportunity for evaluation of the tool.

ARCON HT-SA 35/10, a harp U-shaped collector with a gross area of 13.57 m2, is the most commonly used type in the MeQuSo fields, with 46.6% of the total aperture area installed in CF-1.The pressure drop model of the ARCON collector was successfully developed and validated against measurement data.A similar procedure is currently underway for the other types of collectors in CF-1. The model will be then extended to the entire field. The last step of validation is to model all four collector fields as a network as well as the central pump station comprised of two parallel centrifugal pumps, in which the operation points of the system for single and dual pumping are calculated by the tool. This will then be the first detailed hydraulic model of full large scale collector field.

Federico Bava (Solar Collector Fields for District Heating)

The PhD project at DTU focuses on the development of detailed simulation models of large scale solar collector fields for District Heating applications. A strong collaboration and exchange of information has been established with the Danish company Arcon Sunmark A/S, the world's leading manufacturer of large-scale solar thermal plants for DH. Federico Bava is making the PhD study under the supervision of Assoc. Prof. Simon Furbo (DTU), Assoc. Prof. Jianhua Fan (DTU) and CEO Søren Elisiussen (Arcon-Sunmark A/S).

During the project detailed simulation models for different solar collector types and differently designed and controlled solar collector fields are developed and validated against measurements from the solar collector test facility at DTU and from Danish solar heating plants. This is the next step up in scale compared to the work of Alireza, but in contrast to his work, Federico’s models will be used for improving control during operation rather than just the designing the hydraulic layout.

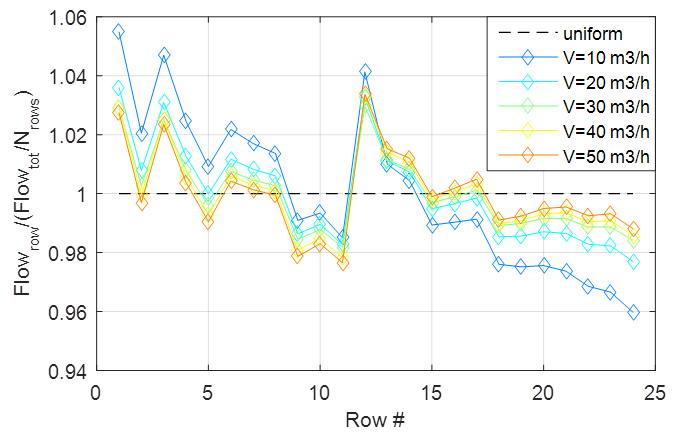

The main model of the collector field is developed in TRNSYS, but it also makes use of a Matlab code to evaluate the flow distribution in the collector field. At present, the flow distribution in Danish solar collector fields is regulated by balancing valves in each collector row. These are set in such a way that a uniform temperature is reached at the end of each row in nominal operating conditions. However, it is not exactly known how the flow distribution is when the field is operated in different conditions such as when the flow is varied with varying radiation. Hence a Matlab code dealing with this aspect has been developed. Figure 2 shows an example of output of the developed model. More specifically, the diagram shows the flow distribution at different flow rates in the collector field by Høje Taastrup (Denmark), when operated at supply/return temperature of 55/95 °C. The dimensionless flow is the ratio of the actual flow rate to that at the design conditions used for setting the balancing valves.

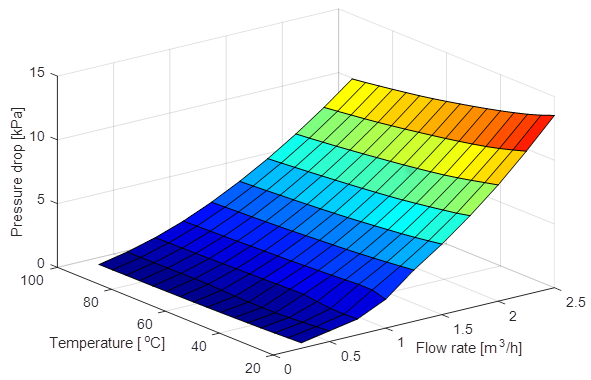

In order to evaluate the flow distribution in the collector field, the relation between flow rate and pressure drop in all the components of the system needs to be known, with the collectors being the most important. Thus, a numerical model to evaluate the pressure drop and flow distribution in a U-type harp collector has been developed. Figure 3 shows an example of the pressure drop dependence on the flow rate and fluid temperature. As can be seen, the pressure drop varies significantly and in practice can range from laminar to turbulent flow. This in turn affects the heat transfer and thus the efficiency of the collector. In order to model this effect, a new TRNSYS type was developed starting from the existing Tess type 539. This new type is able to correct its efficiency parameters depending on the flow regime conditions in the absorber pipes.

As an example application of the tools that he has created, Federico has investigated the techno-economic optimization of collector strings using two types of Arcon-Sunmark collectors (with and without polymer foil).

Yoann Louvet (Investigation of the cost-performance improvement potential of the drainback technology)

Drainback refers to a particular type of solar thermal systems for which frost and overheating protection is provided by the emptying of the collectors when not in operation. Due to this feature, performance improvement and cost reduction can be achieved at the system level. Yoann Louvet is studying this approach under the supervision of Prof. Klaus Vajen from the University of Kassel.

In a first step, an intensive literature research was carried out to summarize available knowledge related to drain-back systems (DBS). Despite being an old technique, few scientific publications were found on the topic. The major source of information turned out to be patents. A mapping of possible system designs as well as state-of-the-art components resulted from this work. Moreover, specific technical issues related to the design and operation of DBS were identified.

Practical knowledge on DBS was gathered from the monitoring of several systems installed by the company EnerSolve GmbH, located in Kassel. In particular, a DBS without a collector-side heat exchanger, that is used for drying of hay bales, was studied in detail. Yoann’s was able to optimize the operation of the plant, notably with regards to the control strategy.

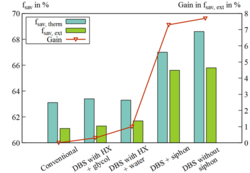

Based on the actual configuration of the plant, a detailed TRNSYS model was built up so that the benefits of using various DBS possibilities could be quantified. These were simulated over the drying season from May to September Figure 4 and 5 compare the thermal performance (indicator fsav,therm) as well as the pumping energy needs (indicator fsav, ext) of the different configurations. It also shows the relative improvement compared to the conventional system with pressurized collector loop. Different drain-back designs were simulated, with and without heat exchanger (HX) in the solar collector loop, with glycol and pure water as heat transfer fluid (HTF), and with and without siphon in the flow pipe. A siphon occurs when the flow pipe is fully filled with HTF. It has a positive impact on the pumping energy needs as it cancels the elevation head, but it might reduce the thermal performance due to cavitation in the collectors. The results showed that the performance improvement due to the use of water instead of an antifreeze mixture is relatively small (< 1 %). On the contrary systems without heat exchanger on the collector-side perform more than 7 % better than the reference.

In parallel to these investigations, a method guaranteeing the safe draining of DBS was developed. It consists in ensuring that no water pocket remains in the solar collector loop after draining. This issue is highly relevant for DBS using water as HTF.

The next steps of the study will consist in simulating a wider range of systems and making parametric studies for these systems. A detailed cost analysis will also be carried out in order to evaluate the overall cost-benefit of solar DBS in comparison to conventional systems.

Nicolás Pérez de la Mora (Optimization of control strategies for a solar district heating and cooling system)

Nicolás’ PhD focuses on the operation optimization of a hybrid power plant which covers the demand of a District Heating and Cooling Network (DHC) and the maximization of solar generation. To do so, he has had to develop electricity price and thermal demand forecasting tools, which work together with an energy simulator. The simulator determinates generation strategies by optimizing the production mix that minimizes the energy cost and maximizes renewable energy fraction. This leads to an optimization of the power plant operation and integration of the solar field. Nicolás is supervised by Vincent Canals and Victor Martinez Moll at University of Balearic Islands (UIB), but is employed and works at the company Sampol Ingenieria y Obras S.A in Mallorca, Spain.

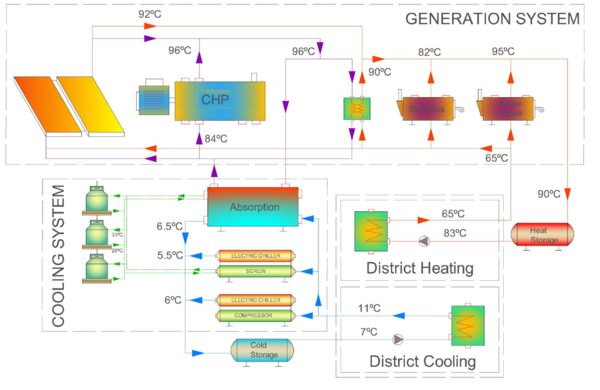

Parc Bit, located in Palma de Mallorca in Spain, is used as a case study for the optimization method. This power plant comprises two Combined Heat and Power (CHP) diesel engines, a biomass burner, a diesel burner, solar collector field, two absorption chillers and two electric chillers as backup. The configuration as well as solar fields and be seen in Figure 6. It is therefore a tri-generation plant that generates heating, cooling and electricity and obtains revenue from injecting electricity into the grid and supplying thermal energy to the DHC. To maximize the plant’s revenue it is necessary to develop algorithms that optimize energy generation strategies to fit generation and demand curves.

In order to guide the power plant manager with these optimal generation strategies a power plant simulator tool has been developed jointly with Politecnico di Torino (PoliTo). This tool is able to optimize the trigeneration plant in different time horizons, using predicted thermal and electric demands, climatic conditions, electricity price forecast, npower plant configuration and machine behavior at different generation points. As an output, the tool provides the schedule of the generation machines, primary energy consumption and total revenue for the time horizon considered.

Nicolás developed a two core forecasting tool based on ARIMAX (Auto Regressive Integrated Moving Average with Explanatory variables) and ANN (Artificial Neural Networks) methods in order to obtain the future electricity prices of the Spanish wholesale energy market and DHC thermal demand. He has also developed a model to calculate the thermal losses in a 4 pipe DHC network that considers the influence between heating and cooling pipes and their working temperatures. The tool takes these losses into account as well as the required pumping energy in the optimization process.

A solar generation forecaster has also been developed, again using two forecasting cores (ARIMAX & ANN) to estimate the future solar thermal generation that can be expected at Parc Bit. This forecast is then used by the optimizer of the overall plant simulator to avoid overlaps with the CHP thermal generation schedule.

The next stage of Nicolás project, he will evaluate the results of the different optimization scenarios and the real-life power plant operation. This comparison will show the influences of forecasting error in the power plant revenue and the differences between the real-life operation and the optimal one. The aim of these comparisons is pursue the modification of real-life generation strategies to improve the power plant management and the maximization of solar fraction.

Artem Sotnikov (Modern planning methodology for local heating networks)

Artem’s PhD project at the software company Vela Solaris AG is supervised by Andreas Witzig at Vela Solaris and Wolfgang Streicher at the University of Innsbruck. The goal was to develop the planning simulation tool Polysun so that it could cover larger and more complex thermal systems. Several heat sources such as solar collectors, geothermal probes, power heat cogeneration as well as the various ways for heat storage were already available at project start. Therefore, the work has focused on extension of existing models to make them more suitable for district heating systems.

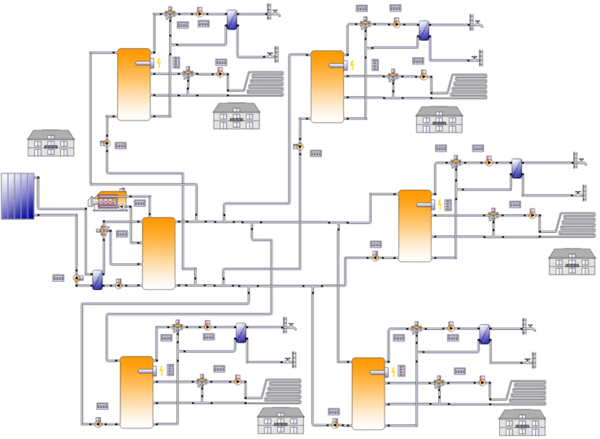

Several existing/new models were extended/developed in the Java programming language, which allows applications to have fast computing time as well as being flexible for possible changes and extensions. The developed models are being calibrated against the TRNSYS simulation software, which is the state-of-the-art tool in the solar energy research field. The first task to be developed was Polysun`s building model so that it can cover multiple residential units within one system boundary (see Figure 7). This also required that several other components necessary for supply of heat to the building be modified.

The next task was to extend two existing models to make them more suitable for district heating applications. The storage model was expanded to allow the user to define number of nodes (instead of the current 12 nodes), making it possible to model stratification better. The pipe modelled was rewritten so that it could also be used for buried pipes. In order to check developed models, a real system at Vallda Heberg has been modelled in Polysun and calibrated against measured data. An article on this and cross-comparison with TRNSYS results is being prepared together with other SHINE PhD students.

The current work is to make a completely new development which will allow simulation of multi-zone buildings with Polysun. A number of physical models of building components were implemented and proven by means of JUnit tests. Now an interface between Polysun and the new model is being built, after which the models will be calibrated against TRNSYS`s Type 56 building model.

Martin Andersen (Techno-economic analysis of centralised and decentralised solar district heating plants)

Martin Andersen is the current PhD student at Dalarna University (SERC), but before that Christian Nielsen worked for a year before leaving in spring 2015. Martin Andersen started autumn 2015 under the supervision of Chris Bales (Dalarna University) and Jan-Olof Dalenbäck (Chalmers University of Technology). The main objective of the project is to derive the techno-economic boundary conditions for profitable integration of solar heat into district heating networks. This will be done for systems where the solar collectors and district heating system are built at the same time (new systems) as well as for retrofit of existing district heating systems with solar heat.

The technical part of the analysis is applied consists of two parts. To firstly examine the operational characteristics of existing solar district heating systems. Then, based on the operational experience from these systems, to collaborate with contractors/utility companies to identify the potential improvement(s) in system configuration and operation. Secondly, suggested improvements are investigated by employment of a validated TRNSYS model of the respective system. The same systems will also be evaluated economically to be able to determine the cost-benefit of the solar part and then, by varying the economic and technical boundary conditions, to determine the range of boundary conditions necessary for profitable operation.

The first system investigated is a novel block-heating system of the Vallda Heberg residential area outside of Gothenburg, Västra Götaland County (Figure 8). The system consists of buildings at near passive house standard with solar thermal integrated at both heating plant and substations. The novelty of the system lies in the use of a domestic hot water circulation with PEX piping (so called GRUDIS) between the substations and the houses for delivery of all heat and simple heating system in the houses. The latter consists of uncontrolled floor heating in the bathrooms (100 W all year round) and controlled heating via the supply air. The advantage with this is the low operating temperatures and very simple (and inexpensive) heat distribution in the houses. The substations are preheated by flat plate collectors and supplied with the rest of the heat via a normal district heating network supplied from the main heating plant. The work is conducted in collaboration with engineering consulting firm Andersson & Hultmark and municipal housing company Eksta Bostads AB, who were responsible for the project.

Preliminary results for two of the four substations in the heating network show that the system is working as intended and that the 40% solar fraction of heat demand is likely to be met. A validated TRNSYS model of one of these substations has been made and simulations is being compared with those from a Polysun model in a future publication. A complete, albeit simplified, TRNSYS model of the entire heating system has been made and calibrated against measured data. This has been used to compare the performance of the existing system with a hypothetical system that has GRUDIS piping throughout, and where the collectors are connected to the stores in the main heating plant. This means that there normal district heating piping is replaced by the GRUDIS pipes and that the collector piping is substantially longer than in the current system. The results show that the total piping losses are substantially reduced, while the net solar gains are reduced somewhat due to the longer pipes. The overall effect is a reduction in the required pellet energy and a lower cost, showing that an all GRUDIS system would be more cost-effective.

Future work will focus on retro-fit of existing district heating networks with solar thermal, in addition to the methodology used to evaluate the profitability in integration of solar thermal into district heating networks.