5th Newsletter (2017 - WP3)

- Focus on Sorption Processes (WP3)

- Trenner

- Numerical and experimental investigations of the adsorption processes in a closed sorption system (Simone Semprini)

- Raster

- Trenner

- Augmentation of closed-loop Absorption / Regeneration units (Federico Lonardi)

- Trenner

- Chemical Aspects of New Storage Materials (Kristijan Krekic)

- Trenner

- Development of a solar seasonal storage concept based on closed sorption (Bao Nam Dang)

- Trenner

- Interview with Kristijan Krekic

- Trenner

- Outreach Activities

Focus on Sorption Processes (WP3)

In sorption processes a material pair is used to release a certain quantity of thermal heat. The process is reversible though. In fact, through the opposite process, named de-sorption, the initial conditions can be re-established, supplying the correct amount of energy under the right thermodynamic conditions, which are needed to trigger the inverse reaction. Considering the amount of enthalpy and the reversibility of the process, sorption can be used for different applications like drying, heating, cooling and storing. Nevertheless, there are currently only few products available. Therefore further enhancements of the sorption materials and the components are necessary to enhance the processes and making sorption economically viable.

Simone Semprini started last year at the Solar & Heat Technology in Stuttgart. His topic is the numerical and experimental investigations of closed adsorption processes. In addition, Federico Lonardi, from the Kassel University, does also experimental investigations with the focus on improving the closed absorber systems with surfactants, while Kristijan Krekic, from the same university, focuses on enhancing sorption materials by means of chemical modification and combination of fluid solid hybrid materials. Furthermore Bao Nam Dang at AEE INTEC in Gleisdorf, doing his research on water evaporation at low pressure for improving closed sorption storages.

Numerical and experimental investigations of the adsorption processes in a closed sorption system (Simone Semprini)

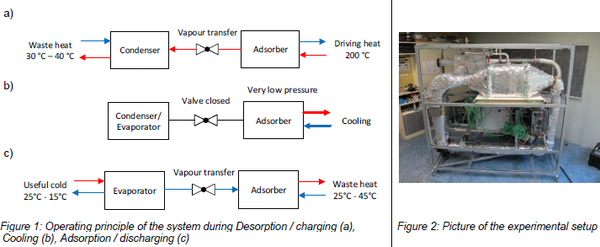

Closed sorption systems work in vacuum conditions and they are composed by at least two components: the adsorber, which includes the solid sorbent, and the evaporator/condenser unit. In this project, water and zeolite 13X are used as working pair. The system work as a thermal battery, which, in this case, is used to store cold energy. The working principle and operating conditions are summarized in Figure 1. The external heat transfer fluid in both components is air, while, internally, the system is filled only by pure water.

The project is divided in two main tasks:

- Development of an experimental setup to test the functioning of the system and to determine the actual performance.

- Development of numerical simulations with its validation through the experimental results.

The experimental prototype has been constructed and tested (Figure 2). The results showed that is possible to store heat and to use it to generate cooling. The prototype was able to generate cooling for 5-6 hours at a constant power of 500 W. On the other hand, the two main problems in designing and operating such system have been identified as the low heat transfer coefficient of the zeolite and the high vacuum tightness needed. These conditions posed some problems in designing an efficient adsorber.

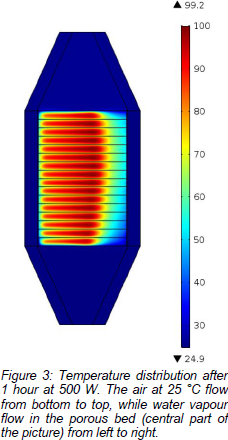

The simulation model has been developed in COMSOL™. It includes a 2D model of the adsorber and 0D model. The model couples heat and mass transfer for air, zeolite bed and water, sorption equilibrium and kinetics and evaporation/condensation kinetics. Figure 2 reports an example of the solution for the temperature field during adsorption.

The model is able to predict coherently the main operatingconditions of the system. Nevertheless, the adsorptionkinetics was not always perfectly reproducible. It has beensimulated by the Linear Driving Force model, which is widelyused in literature, but there are not much data available forclosed systems working in highly non-stationary conditions.Therefore, the next steps of the investigation focuses on thesimulation of the kinetics of the sorption process at themicroscale level (pellet dimension) with the aim to prove theapplicability of the model for the conditions of the system.

Augmentation of closed-loop Absorption / Regeneration units (Federico Lonardi)

Absorption chillers can provide a cooling demand with low electrical energy consumption. Indeed, such chillers are driven by low-temperature heat, which can be provided by means of solar thermal collectors and/or is often available as waste heat in the industry. On the other side, these chillers are still characterized by large sizes and high costs of investments. In this framework, an optimization of them is a crucial task to perform in order to reduce costs and encourage a wider spreading of this technology on the market. The PhD project of Federico Lonardi focuses on experimental investigations on the coupled heat and mass transfer mechanism in the absorber, which has been widely recognized as the limiting component of an absorption chiller [1]. The aim is a deep understanding of the enhancement mechanism of alcoholic additives, which increase the heat and mass transfer when added in small quantities to the working fluid (aqueous lithium bromide solution). This work is carried out at the Department of Technical Thermodynamics of the University of Kassel under the supervision of Prof. Dr.-Ing. Andrea Luke.

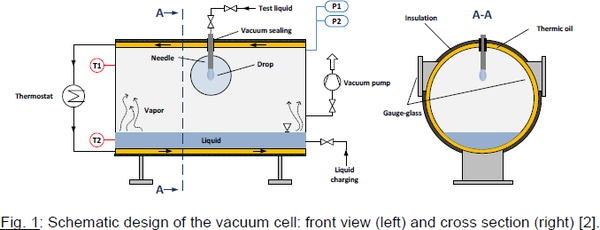

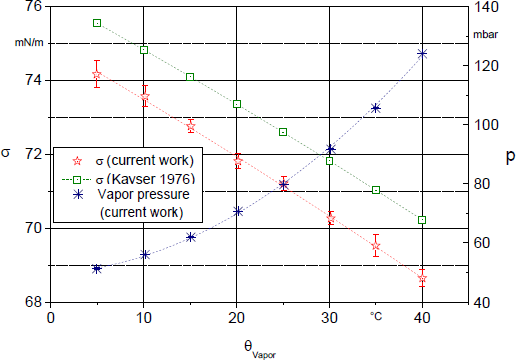

In the first part of the project, a vacuum cell was developed and brought into operation. This cell allows measurements of the surface tension of aqueous lithium bromide solutions with additives at low pressure in a saturated atmosphere, thus representing the real working condition of the absorber. The surface tension characterizes the wettability of the tube bundle of the absorber. A schematic of this apparatus can be seen in Fig. 1. The test-rig has been validated with previous literature (Fig. 2).

In the second part of the project, experimental investigations on the enhanced heat and mass transfer of a falling film absorber with different additives in the aqueous LiBr solution are carried out. The experimental test-rig consists of a closed-loop falling-film absorber with a horizontal tube bundle made out of copper tubes [1]. Based on the measurements carried out in the whole project, a correlation for the optimal design of the absorber will be developed and new additives will be proposed.

[1] Tomforde, C., Luke, A: Experimental Investigation of the Transport Phenomena on aFalling Film Absorber with Microstructured Tubes. Proceedings of the International SorptionHeat Pump Conference, College Town, USA, 2014

[2] Lonardi, F., Tomforde, C., Luke, A.: Experimental Investigation of Marangoni Convectionand Surface Tension of Aqueous Lithium Bromide Solutions with Additives at Low Pressure.12th IIR Gustav Lorentzen Natural Working Fluids Conference, Edinburgh, UK, 2016

Chemical Aspects of New Storage Materials (Kristijan Krekic)

We are especially interested in (ad-)sorption processes involving solid or liquid phases which can be carried out in open or closed systems. Some of these systems are commercially available to date, however the sorption materials currently in use are subject of improvement. In this Ph.D. project the focus is set to the development and modification of novel desiccant sorption materials which may be solid, liquid or a combination of both. Existing solid sorption phases suffer from limited sorption capacities, mediocre thermal properties and space-filling as well as diffusion limited mass transport from the surface to the bulk material. On the other hand liquid desiccant phases are often corrosive, toxic and expensive. Therefore, in addition to established storage materials the potential of new types of solid and liquid desiccants like metal organic frameworks (MOFs) and ionic liquids (ILs) are explored aiming at applications involving energy storage and conversion. In the course of the project materials and material combinations are assessed based on literature data (if available) but also experimentally (e.g. isothermal titration calorimetry, water vapor pressure, desorption conditions, etc.). To improve their desirable properties, structural modifications on a molecular level will be carried out to optimize physical properties relevant to heat and mass transfer as well as to storage capacity.

Several materials were investigated by isothermal titration calorimetry. Prior to the titration experiment desorption of water was carried out by heating and evacuation in a sealed tube. The applied temperatures range from 100°C (for silica gel) to 200 °C (for zeolite 13XBF) in order to fully dry the specific material. According to the titration experiments zeolite 13XBF shows the best adsorption enthalpy (integration of whole adsorption range). MOF-199, even though it has a lower adsorption enthalpy desorbs water at a much lower temperature of 120 °C, rendering it better suited for regeneration processes. MOFs with structural similarities to zeolites, MIL-101-M3 (M= Fe, Cr, Al), show a lower adsorption then zeolite, albeit lower desorption temperature (140 °C) and higher water uptake.

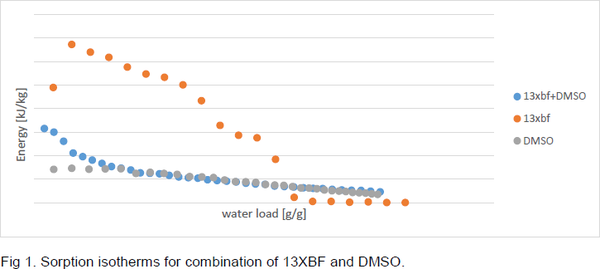

Current experiments are based on improving poor heat conduction of solid materials. For that we are introducing new model. By using combination of solid and liquid we are not only improving heat conduction of system but also the water load capacity. Until now several liquids were tested in combination with zeolite 13XBF. First test show an increase in heat conduction and water capacity but water load on zeolite is reduced due to competition of liquid and water. Based on this results dimethyl sulfoxide (DMSO) as liquid was used, showed on fig 1. Future experiments will be carried using different liquids in order to find best potential match.

Development of a solar seasonal storage concept based on closed sorption (Bao Nam Dang)

Thermal storages are one of the key technologies for efficient solar thermal systems. Until now mainly large water storages are used, which have the drawback that water possesses a relatively low energy density (~ 60 kWh/m³). Thus, large storage volumes are needed to cover a high amount of the heat demand for domestic hot water and space heating. One promising alternative is the sorption storage, which has a higher energy density. It is based on the endothermic decomposition and exothermic binding process of two substances. Thermal energy will be saved, as long as both substances are kept separately from each other. Furthermore they are both stored at ambient temperature, so no heat losses occurs. At AEE INTEC a closed adsorption storage system for a single family house was built in the laboratory at AEE INTEC. This system used the material pair zeolite and water and was successfully demonstrated over the winter period with a solar fraction of 83.5 % and an energy density around 180 kWh/m³. However, further improvements on the material and the components are necessary to increase the performance and lower the system costs, wherefore the objectives of this work package have been changed. Bao Nam Dang’s PhD project investigates the evaporator, which is one of the critical components in the closed sorption system. The aim is to extend and deepen the knowledge on the evaporation of water at sub-atmospheric pressure conditions, which allows to design and to operate an efficient evaporator and thus improving also the storage system. This work is carried out at AEE INTEC in Gleisdorf with Dr. Wim van Helden as supervisor.

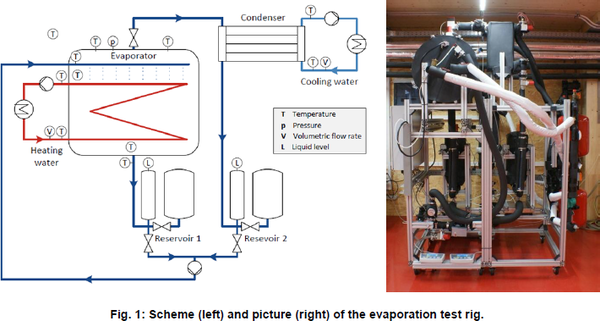

For the experimental investigations on different heat exchangers a test rig was built. As shown in Fig. 1, it consisted of a cylindrical vessel, which contains the tested evaporator. Further components are the condenser and two reservoirs in the bottom part of the test rig. Since the reservoirs have liquid level sensors, the evaporation power can be determined by the speed of the changing liquid levels. Furthermore, the power can be also calculated with the measured inlet and outlet temperatures and the mass flow of the heating water and the cooling water circuit.

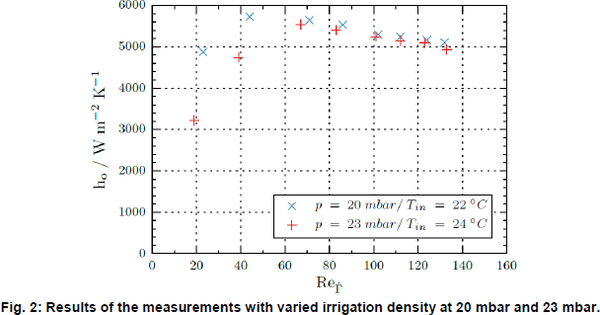

First experiments were done on a falling film evaporator with a copper tube bundle with saturation pressure below 25 mbar. For example, Figure 2 shows the measurement results for the evaporation heat coefficient in dependency of the saturation pressure and the Reynolds Film number. Both measurement series have almost the same characteristic with the peak value at around 40. On the one hand with lower irrigation, the heat transfer coefficient starts to decline since dry out sports occurs on the tubes. On the other hand, with increasing irrigation the film thickness and hence the thermal resistance increase, so the heat transfer coefficient also dropped.

The next steps would be to continue the experimental investigations with larger density and range of the different geometrical and operational parameters, like the like tube’s diameter and spacing. In addition other evaporators will be tested and then compared with each other. The gained measurements will be then used for designing an evaporator, which will be tested under real operation in a sorption storage system.

Interview with Kristijan Krekic

Tell us about yourself, Kristijan.

Hello, I come from Croatia where I studied Chemistry and obtained my masters. During my masters I have participated in promotion of science to younger generations (elementary and high school). After I obtained my masters in chemistry I decided to shift my focus from the basic science to more applied one.

How did you meet the SHINE project?

It was at the end of my masters that my supervisor told me that there is new project that requires a chemist and is in field of applied science. I then decided to apply and try myself in a field that was somehow new to me.

Why did you decide to apply to be part of SHINE?

As I said it was something new to me. But there were other factors that were decisive. First was the opportunity to collaborate with engineers in making new and better technology. Second was a chance to learn more about solar technology from the experts in the field. Also big influence had the possibility of collaboration not with just groups at your own university but also with others across Europe.

How does Chemistry fit in an engineering project?

Well in the whole project it does not fit so well outside providing some small guidance about materials. On the other hand in work package 3 it fits perfectly. Here we are working on better understanding sorption processes in order to develop better seasonal storage systems. My part as chemist is to provide input about materials (stability, availability, properties, etc.), as well as providing very detailed sorption properties that could possibly help to better understand the adsorption process and update the existing models.

Have you participated in the previous PhD courses in SHINE?

Yes I participated in all of them since begin of the project.

How did the courses influence your research?

Those courses helped me to expand my knowledge about solar thermal technology. That knowledge helped me to identify where to focus my research. Also the course in Kassel that was given by us students helped not only my research but also my teaching skills.

Outreach Activities

11th International Renewable Energy Storage Conference 2017 (IRES)

The 11th IRES-Conference took place on March, 14th -16th in Düsseldorf (Germany). The focus of this event was on the recent advances in the storage field, both thermal and electrical, discussing the applicability and need for storage in the power, heating and transport sectors.

The three-day program featured a conference and an exhibition, in order to connect the academic world with the business reality. The conference consisted of different poster sessions, presentations and talks, while the exhibition spaced from the latest technologies available on the market to the applicability of the same in decentralized energy supply systems.

The Work Package 3 of the SHINE Project had a slot in the presentation session “Sorption Storage for Solar Heat”, where the whole SHINE project was introduced and the latest results of the WP-3 were presented and discussed. The presentations are listed below:

- Krekic, K.: Thermal and Dessicant properties of Sorption Media

- Dang, B.N.: Investigation of Water Evaporation for Closed Sorption Storage System

- Semprini, S.: Eperimental and Numerical Investigations of an Adsorption Storage for Cooling Applications

- Lonardi, F.: Heat and Mass Transfer of a H20/LiBr Falling Film Absorber with a Horizontal Tube Bundle

Additional information on the conference, as well as the whole program, can be found at: http://www.eurosolar.de/en/index.php/events/ires-conference-eurosolar