Structural Materials and Construction Chemistry

Atomistic Modeling of Cement Hydration

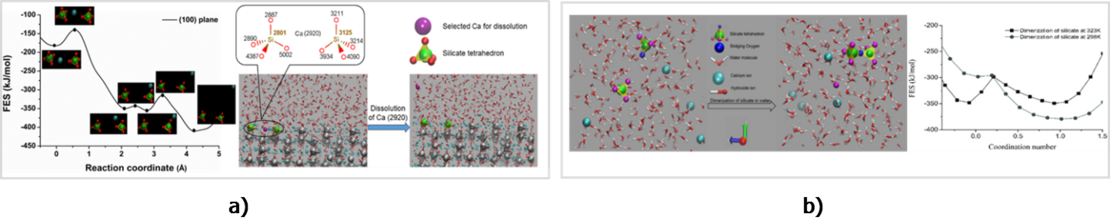

Concrete is the world’s most used construction material and cement is one of the key ingredients of concrete, which is composed of mainly a solid mixture of different clinker phases. Tricalcium silicate (C3S, alite, Ca3SiO5) is the major constituent and relatively most reactive phase in Ordinary Portland Cement (OPC). Therefore, many experimental studies have been done in order to investigate the hydration mechanism by using C3S as a model system. Cement hydration is a complex reaction process involving the concomitant reaction of many mineral phases. Hydration mechanism, especially early hydration at atomistic scale are not fully understood yet due to limitations of experimental techniques. Atomistic simulation using Reactive Force Fields (ReaxFF), in combination with metadynamics (MetaD) can be an effective solution to study the chemical reactions pathways with sufficient accuracy and reasonable computing times. This combined approach has shown great potential and allowed to study the early hydration of C3S. In this project, the reactivity and thermodynamic stability of different crystal planes of C3S were calculated from the dissolution profile of calcium during hydration at 298 K. The simulation results, clearly describe the higher reactivity of (011), (011), (100), and (100) surfaces of C3S due to the strong interaction with the water, whereas, the dissolution profile explains the lower reactivity of (110), (110), (010) and the effect of water tessellation on the (001), (010) planes. The polymerization mechanism of silicate during hydration at different external parameters (i.e. temperature, Ca/Si ratio, etc.) also have investigated in this project. The dimerization of silicate in pore solution is involved 5 oxygen coordinated silicon intermediate. Moreover, the barrier-less dimerization process at room temperature (Ca/Si is 2) has explained the dimer formation in the dormant period during hydration. Moreover, the Ca/Si ratio is the influential factor to build either dimeric or polymeric C-S-H. As Ca/Si ratio increases, the polymerization of silicate become thermodynamically unfavorable.

Project-related Publications

Salah Uddin, K. M.; Middendorf, B. (2019), Reactivity of different crystalline surfaces of C3S during early hydration by the atomistic approach, Materials 2019, 12(9), 1514; doi.org 10.3390/ma12091514

Salah Uddin, K.M.; Middendorf, B.; Atomistic modeling of early Hydration of C3S; Meschke, Günther; Pichler, Bernhard; Rots, Jan G. (Eds.) (2018); Computational Modelling of Concrete and Concrete Structures (EURO-C); CRC Press/Balkema: Leiden, Netherlands. ISBN 9781315182964 (eBook)

Shape Memory Alloys in Research and Technology for Construction (SmartCon)

SMA are well known for applications in medicine, robotics and aerospace. However, in civil engineering only since the early 1990s the material was part of research but has seen only few practical applications. Currently a DFG-Project (SmartCon) is planned to investigate the usage of SMA in form of fiber reinforcement in UHPC at the department of Prof. Middendorf in cooperation with several other departments of the university of Kassel, including Prof. Niendorf (Metallic materials, Faculty 15) as an active CINSaT member.

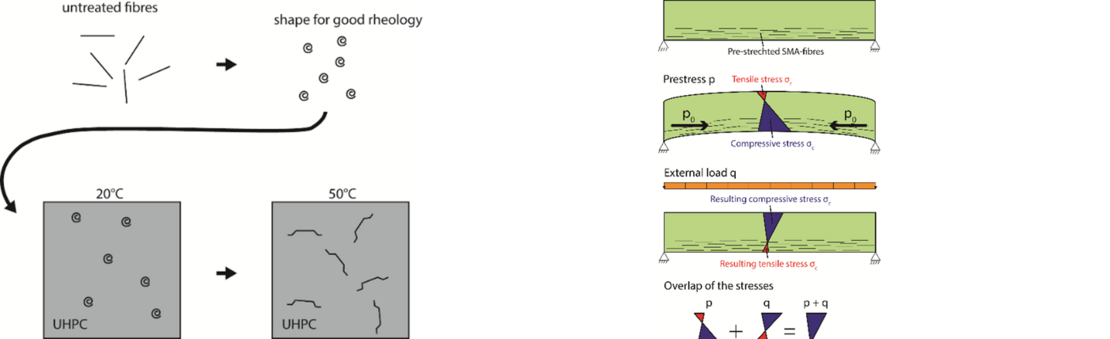

In this project two effects of SMAs will be employed to realize smart construction materials. On the one hand, the mechanically activated pseudoelasticity can be used within timber, or concrete constructions in order to damp vibrations, which might be generated by wind or by earthquakes. On the other hand, the one-way effect can be used to improve the properties of fiber-reinforced concrete. Here, SMAs will be used as fibers. Since several years, the groups of Prof. Middendorf and Prof. Fehling are investigating ultra-high performance concrete, which necessitates micro-fibers to make filigree constructions possible. These functional fibers will be used in different ways. In one approach, the fibers have the aim to improve the mechanical properties of the concrete without a significant deterioration of the fresh concrete´s workability (Figure 1a). Therefore, the fibers are formed in a shape that is favorable for the rheological properties of the fresh concrete. After addition of the fibers, the shape memory effect will be activated due to thermal, magnetic or inductive treatment while the concrete is still flowable. Due to this activation the fibers transform into their imprinted geometry that is favorable for the mechanical properties of the hardened concrete. On the other hand, the fibers will be used to prestress concrete components (Figure 1b). Pre-stretched, straight SMA fibers are added to the fresh concrete. In cooperation with Prof. Wünsch (Fluid Mechanics, Faculty 15) the distribution and orientation of the fibers will be investigated and modelled to use the shape memory effect in the most effective way. After hardening of the concrete, the fibers will be activated resulting in a stress transmission from the fibers, that intend to contract themselves as they are stretched, to the concrete. This prestress will counteract the stresses that the concrete component will receive in its later function.

For both approaches the bonding between fiber and cementitious concrete matrix is an essential factor in regard to the effectivity of the method. Therefore, micro- and nanostructural investigations of the interfacial transition zone between the two materials will be carried out to get a better understanding of the combination of the materials. These investigations will include SEM, µ-CT, TEM, light microscopy and other analytical methods.

Project-related Publications

Schleiting, M.; Wetzel, A.; Krooß, P.; Thiemicke, J.; Niendorf, T.; Middendorf, B.; Fehling E. Functional microfibre reinforced Ultra-High Performance Concrete (FMF-UHPC), Cement and Concrete Research, in review

Prof. Dr. Bernhard Middendorf

full member

- Telephone

- +49 561 804-2601

- middendorf[at]uni-kassel[dot]de

- Location

- Universität Kassel

Fachbereich 14 - Bauingenieur- & Umweltingenieurwesen

Institut für konstruktiven Ingenieurbau

Mönchebergstraße 7

34125 Kassel

- Room

- 1109