Metals Group

The Metals group focuses on process-microstructure-property-relationships in a huge variety of metallic alloys. In focus of research are metals processed by additive manufacturing (AM) as well as stemming from traditional machining. Characterization of microstructure includes several length scales from micron-regime to the nano-regime. For characterization in the nano-regime mainly transmission electron microscopy (TEM) is employed, however, further techniques such as computed tomography, atomic force microscopy and atom probe tomography (APT) as well as X-ray, neutron and synchrotron scattering are considered.

Activities in the field of AM using selective electron beam melting (EBM) and selective laser melting (SLM) mainly focus on the role of microstructure on the properties and damage evolution of diverse alloys. Ti-6Al-4V, steels, Ni-base superalloys, Al-alloys and further alloys are thoroughly characterized. Especially in Ni-base superalloys such as INCONEL718, Al-Si alloys and tool steels such as H13, features on the sub-micron scale strongly affect the final mechanical properties. Size and appearance, respectively, of these features on the nanoscale are fundamentally different to their conventionally processed counterparts. Differences are mainly stemming from unique characteristics of AM processes. AM components are processed layer-wise, each layer is characterized by distinct features. With respect to the overall dimensions, the melt pool induced by the beam source employed is very small leading to rapid solidification upon source deflection. Furthermore, materials are heat treated intrinsically as heat induced in the uppermost layer will have to penetrate through the already solidified material. In consequence, alloys such as the Ni-base superalloy INCONEL718 are characterized by unique micro- and nanostructures as thermal history strongly influences their final appearance.

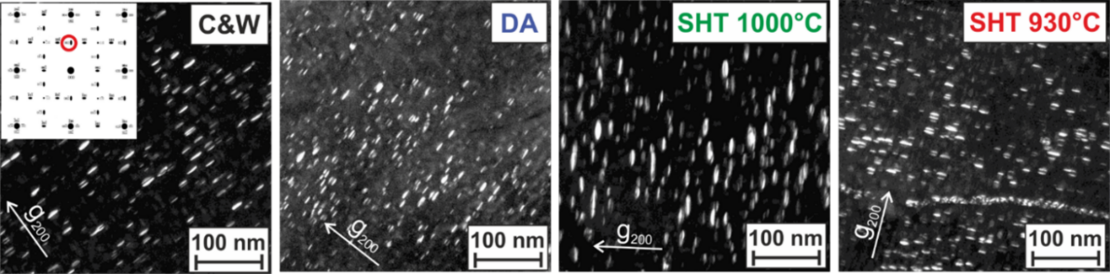

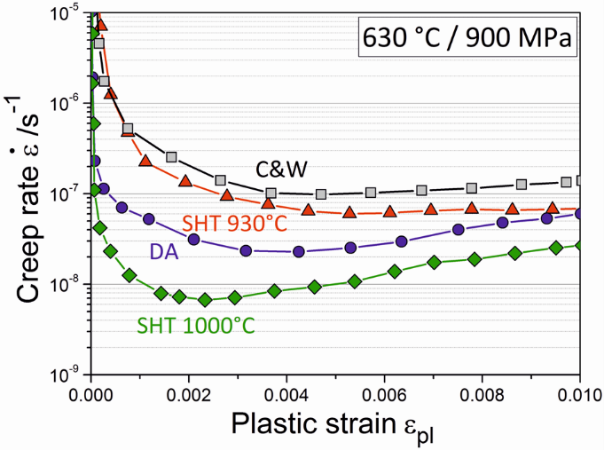

Figure 1 reveals precipitation characteristics on the nano-scale resolved by TEM. In the as-built, e.g. non post-treated condition, the alloy is dominated by sub-micron scale dislocation cells, concomitant segregation of heavy elements and process induced evolution of the detrimental Laves phase. Subsequent post-process heat treatment leads to the evolution of nano-scale [gamma]’ and [gamma]’’ precipitates. As is revealed by APT, arrangement of these phases resembles a stacked layer sequence with the [gamma]’ precipitates embedded within [gamma]’’ platelets. The unique micro- and nanostructures lead to superior mechanical properties in the AM processed conditions as is exemplarily shown in Figure 2 highlighting the creep behavior of AM processed and post treated INCONEL718 alloy conditions in comparison to their conventionally processed counterpart.

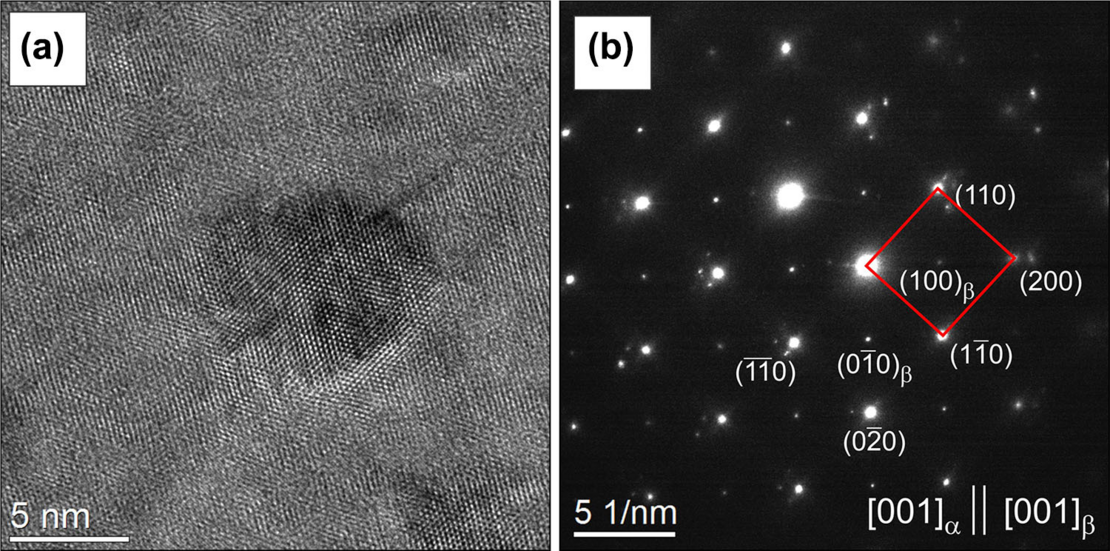

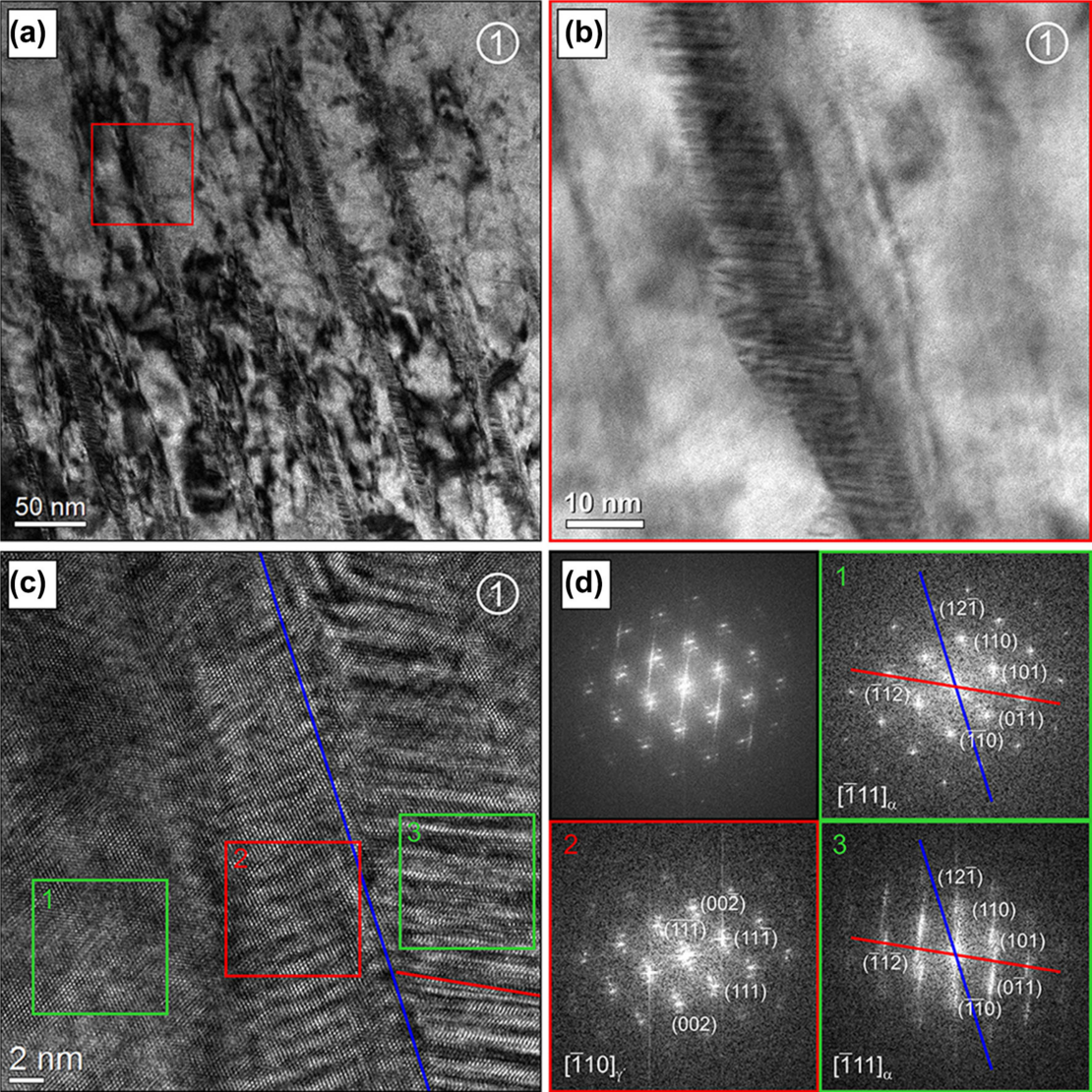

A second major research topic in the Metals group is shape memory alloys (SMAs). Based on a fully reversible solid-solid phase transformation from a high-temperature austenitic phase to a low-temperature martensitic phase SMAs can fully recover their original shape upon deformation, either triggered by heat or mechanical stress, depending on application temperature. SMAs are known to be highly influenced by evolution of chemical composition and lattice defect arrangement on the nano-scale. Focus in SMA research in the Niendorf Group is on novel high-temperature SMAs and Fe-base SMAs. For establishing good shape memory behavior and pseudoelasticity, respectively, in most novel SMAs the presence of nano-scale precipitates is crucial. Figure 3 highlights the appearance of B2-ordered precipitates in Fe-Mn-Al-Ni SMA after aging treatment at 200 °C. Only in presence of these precipitates the material shows a thermo-elastic martensitic transformation. At the same time, however, deterioration of the functional behavior of the alloy is strongly promoted by these precipitates. Significant increase of dislocation density is observed upon detwinning of the martensite and seems to be strongly influenced by the precipitates (Figure 4).

Figure 3: Nano-scale β-phase precipitate in Fe-Mn-Ni-Al SMA upon aging for 3 h at 200 °C [2].

Similar observations have been made in case of Co-Ni-Ga Heusler-type SMA. Aging at 350 °C promotes formation of nano-scale coherent ’ L12-ordered precipitates. As in case of the Fe-base SMA these precipitates feature a size of about 10 nm. In situ mechanical characterization using optical microscopy, atomic force microscopy (AFM/MFM; in collaboration with the Ehresmann Group) as well as neutron diffraction revealed that the presence of these precipitates strongly alters martensite variant selection, magnetic domain structure and eventually mechanical response. Furthermore, energy dissipation per cycle and functional fatigue are strongly affected.

Results revealed that in all novel SMA systems establishment of precipitates of a given size in between 5 to 15 nm seems to be very beneficial for functional properties. However, precipitates being too large deteriorate especially function stability by promoting dislocation evolution and, thus, plasticity induced stabilization of martensite hindering back transformation (cf. Figure 4). Studies focusing on the nature of martensite-dislocation interactions currently are in focus and will be further studied by in situ neutron- and synchrotron diffraction analysis as well as TEM.

Figure 4: Elementary deformation mechanisms contributing to functional fatigue of Fe-Mn-Al-Ni SMA [2].

References

[1] M. Pröbstle, S. Neumeier, J. Hopfenmüller, L.P. Freund, T. Niendorf, D. Schwarze, M. Göken: Superior creep strength of a nickel-based superalloy produced by selective laser melting, Mater. Sci. Eng. A674, 2016, 299-307.

[2] M. Vollmer, M.J. Kriegel, P. Krooß, S. Martin, V. Klemm, A. Weidner, Y. Chumlyakov, H. Biermann, D. Rafaja, T. Niendorf: Cyclic degradation behavior of 〈001〉-oriented Fe-Mn-Al-Ni single crystals in tension, Shape Memory and Superelasticity 3, 2017, 335-346.

Prof. Dr. Thomas Niendorf

full member

- Telephone

- +49 561 804-7018

- niendorf[at]uni-kassel[dot]de

- Location

- Universität Kassel

Fachbereich 15 - Maschinenbau

Institut für Werkstofftechnik / Metallische Werkstoffe

Mönchebergstraße 3

34125 Kassel