This page contains automatically translated content.

Higher strength for metals with defect engineering

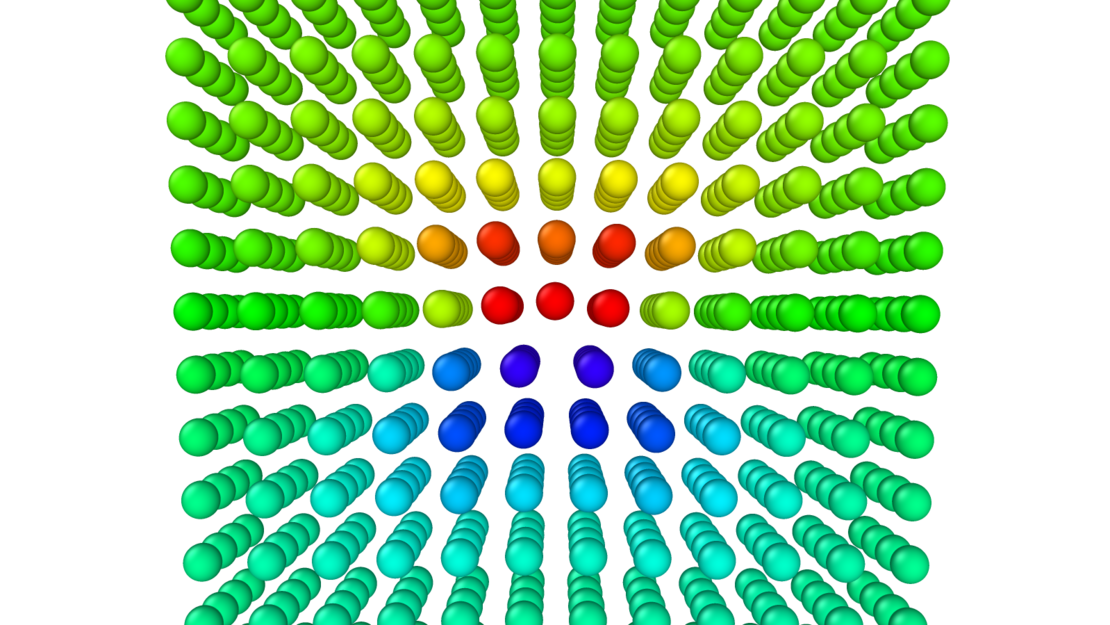

Image: University of Kassel

Image: University of KasselAn international research team involving the University of Kassel has now shown that an unexpected potential can be tapped here. Using a novel approach from defect engineering, it has been possible to increase conventional dislocation strengthening by up to 40 percent.

Why 40 percent is a milestone

In materials science, improvements of just a few percentage points are often considered significant. An additional 40 percent strengthening based on a decades-old concept is considered extraordinary - especially as many experts had assumed that the limits of classic dislocation strengthening had already been reached.

This is precisely why the targeted use of chemically modified dislocations opens up new perspectives for the development of lighter but significantly more robust components for electromobility and aerospace.

The key lies in so-called linear complexions. In this process, certain atoms specifically accumulate along the dislocation lines. These chemical enrichments lead to the formation of extremely small, ordered structures in the nanometer range, which hinder the movement of dislocations much more effectively than conventional mechanisms and thus make the materials more robust.

The work was carried out in close cooperation with the University of California, Santa Barbara (UCSB) under the direction of Prof. Dan S. Gianola, a leading international scientist in the field of modern structural materials. The Kassel group of Prof. Benoit Merle (Institute of Materials Engineering, Department of Mechanical Behavior of Materials) contributed its special expertise in nanomechanics and nanoindentation.

The sub-project from Kassel was funded by the European Research Council (ERC) as part of the EU's Horizon 2020 research program (Grant Agreement No. 949626).

The results were published in the renowned international journal Acta Materialia: Howard et al.: "Chemically ordered dislocation defect phases as a new strengthening pathway in Ni-Al alloys" (2025), https://doi.org/10.1016/j.actamat.2025.120887