This page contains automatically translated content.

Model factory of the University of Kassel honored at the Hessian University Award for Excellence in Teaching

Image: University of Kassel

Image: University of KasselThe "μPlant" model factory project received recognition worth 3,000 euros at the Wiesbaden Museum. The first prize, another recognition and a prize for a student project went to Frankfurt, Darmstadt and Marburg.

Science Minister Boris Rhein commented: "I warmly congratulate the prize winners and the nominated projects on their success. Their teaching concepts

are practical and forward-looking. They give students new perspectives on problems and encourage them to approach both theoretical learning material and practical issues in a variety of ways."

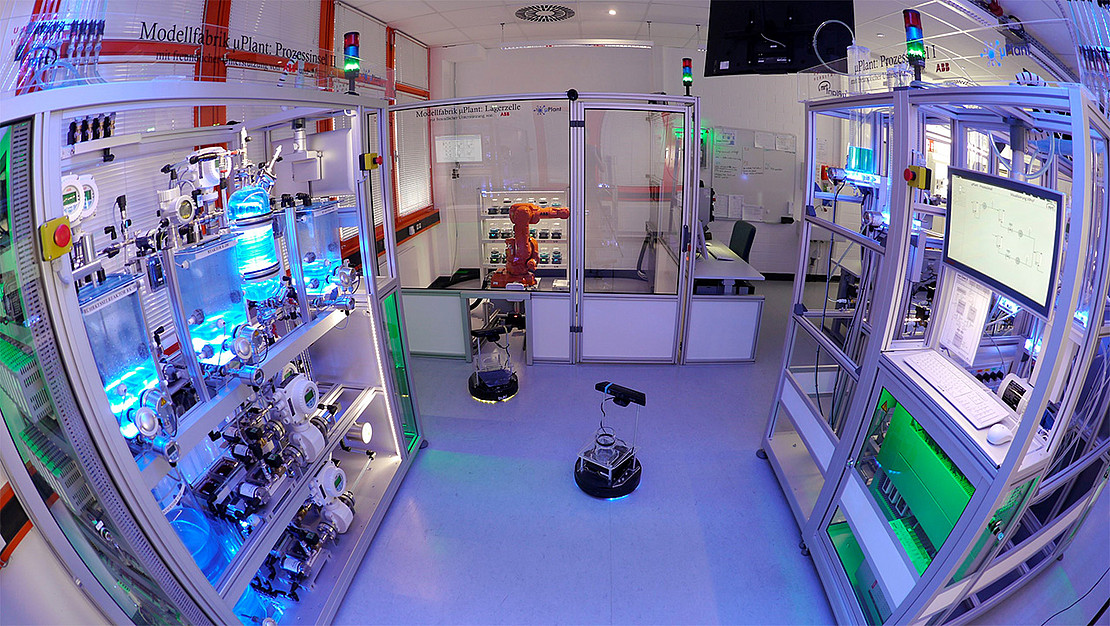

The model factory was largely developed and built by and with students and consists of six stations that communicate with each other as well as autonomous mobile robots and a control station from which the plant is monitored. Mechanical engineering and mechatronics students in Kassel are using the plant to learn how to develop, control and monitor systems for Industry 4.0. It enables fully automated production processes to be mapped and methods to be researched, for example, for the early detection (or even prediction) of faults in an automated, networked and heterogeneous factory. In this way, critical situations can be provoked in a targeted manner, repeated as often as desired, analyzed and methods for improvement developed.

The facility was built since 2011, successively put into operation and officially inaugurated at the beginning of 2017. "Our aim is to offer students training in present and future technologies," explained Prof. Dr.-Ing Andreas Kroll, head of the Department of Measurement and Control Engineering. The recognition by Minister of State Rhein is a very motivating confirmation for all involved. The model factory "μPlant" is a project of Prof. Kroll, Johann Pankratz, Axel Dürrbaum, David Arengas, Hassan Al Mawla, Benjamin Jäschke and Dr.-Ing. Andreas Geiger.

The President of the University of Kassel, Prof. Dr. Reiner Finkeldey, congratulated: "This recognition is further proof that the University of Kassel is a place of exceptionally good and practical teaching, also and especially in technical subjects."

Photo:

View of the model factory: two process islands with storage cell and robots (Photo: University of Kassel):

http://www.uni-kassel.de/uni/fileadmin/datas/uni/presse/anhaenge/2016/_1110462.jpg

More pictures available on request from the press office of the University of Kassel: presse[at]uni-kassel[dot]de

The images can be used free of charge for one year and only in connection with this press release.

Contact:

Sebastian Mense

University of Kassel

Communication, Press and Public Relations

Tel.: +49 561 804-1961

E-mail: presse[at]uni-kassel[dot]de

Prof. Dr. Andreas Kroll

University of Kassel

Institute for Analysis and Control of Technical Systems (ISAC)

Department of Measurement and Control

Tel.: +49 561 804-3248

E-mail: andreas.kroll[at]mrt.uni-kassel[dot]de