This page contains automatically translated content.

Novel "sandwich wall" made of ultra-high performance and foamed concrete

Image: University of Kassel.

Image: University of Kassel. Image: University of Kassel.

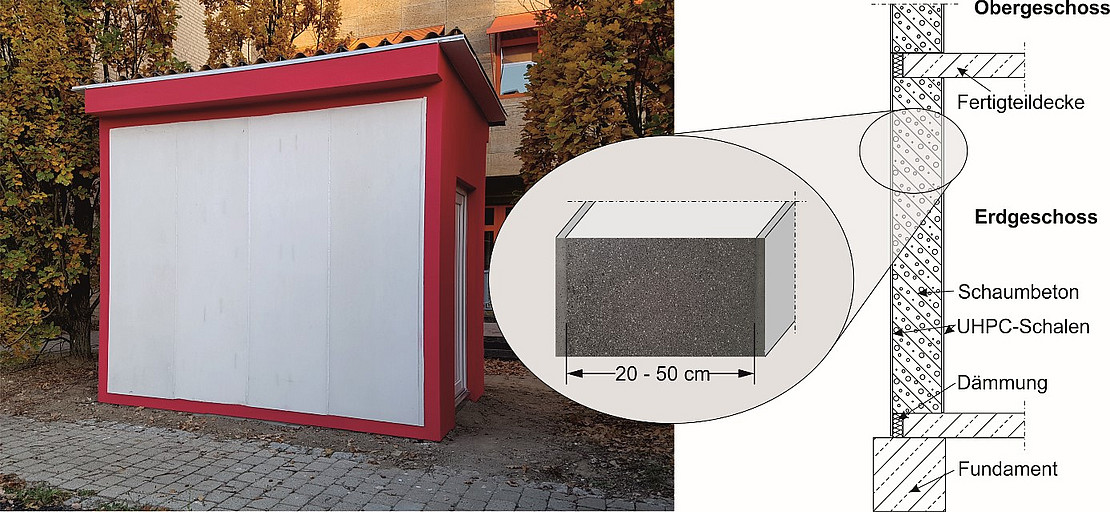

Image: University of Kassel.The development relies purely on mineral materials: two layers of ultra-high performance concrete (UHPC) surround a heat-insulating and load-bearing core of chemically expanded and air-hardening foamed concrete. The UHPC is concreted against the foamed concrete body, resulting in a good bond and thus a high resistance to applied loads. In the event of possible later deconstruction, the layers are nevertheless easily separable and easy to recycle - quite different from conventional wall elements in which various mineral and organic building materials are bonded by adhesive.

To achieve the highest possible strength combined with good thermal insulation, the scientists optimized the pore distribution and structure of the foamed concrete; an additional addition of lightweight aggregates, as used in structural lightweight concretes, was also considered in the investigations. The air-hardening foamed concrete has the advantages that it can be placed in any mold, can therefore be produced regardless of location, foams up there and does not require energy-intensive "autoclaving," i.e. hardening at high pressure and temperature.

"Our wall element can be manufactured at low cost and is characterized by very low repair costs and a long service life," note scientists Prof. Dr. Bernhard Middendorf and Dr. Alexander Wetzel from the Department of Materials in Construction and Construction Chemistry at the University of Kassel. "It has excellent thermal insulation properties and, in combination with its complete recyclability, makes a significant contribution to environmental protection."

The multifunctional sandwich elements are predestined for modular construction with prefabricated components. The Kassel scientists, who include the team of Prof. Dr.-Ing. Ekkehard Fehling from the Department of Solid Construction, favor their use in the construction of industrial halls and large residential complexes, but also in the addition of floors to existing buildings. They have already established contacts with industry to bring the development to series maturity. A prototype building with the sandwich elements in the form of a pavilion has been erected for long-term measurements on the campus of Kassel University at Holländischer Platz.

The project was funded by the Zukunft Bau research initiative, an initiative of the German Federal Ministry of the Interior, for Construction and Home Affairs (BMI).

Contact:

Prof. Dr. Bernhard Middendorf

Department of Materials in Construction and Construction Chemistry

Tel.: 49 561 804-2602

E-mail: middendorf[at]uni-kassel[dot]de

Sebastian Mense

University of Kassel

Communication, Press and Public Relations

Tel.: +49 561 804-1961

E-mail: presse[at]uni-kassel[dot]de

www.uni-kassel.de